Sustainable Practices

We take a realistic approach to sustainability.

Nobody is perfect when it comes to leaving a zero carbon footprint, but everyone can do their best to minimize impact at any scale.

At the end of the day, we are still consuming and purchasing materials to create our products.

We demonstrate sustainability through our messaging and manufacturing practices.

What are the materials used?

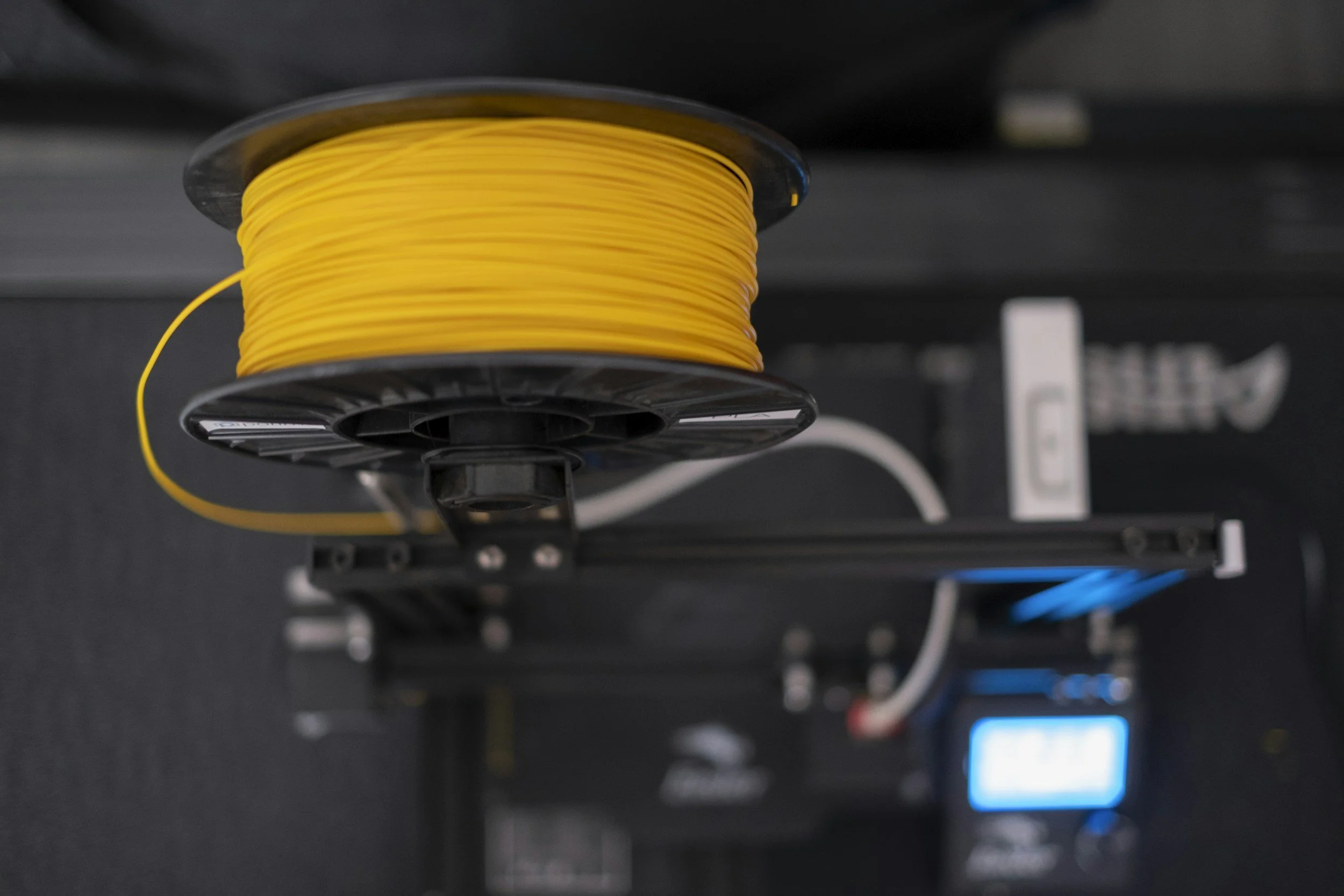

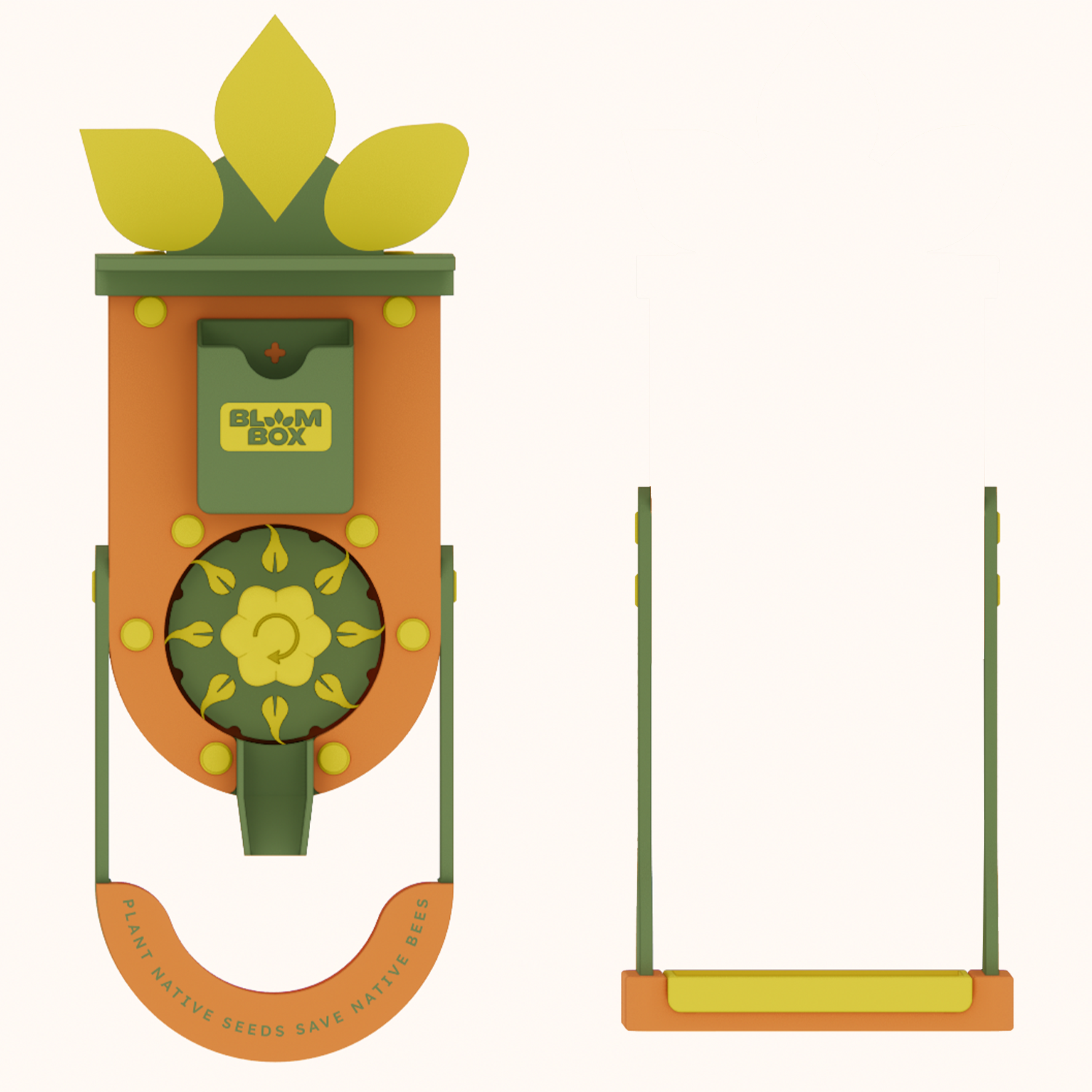

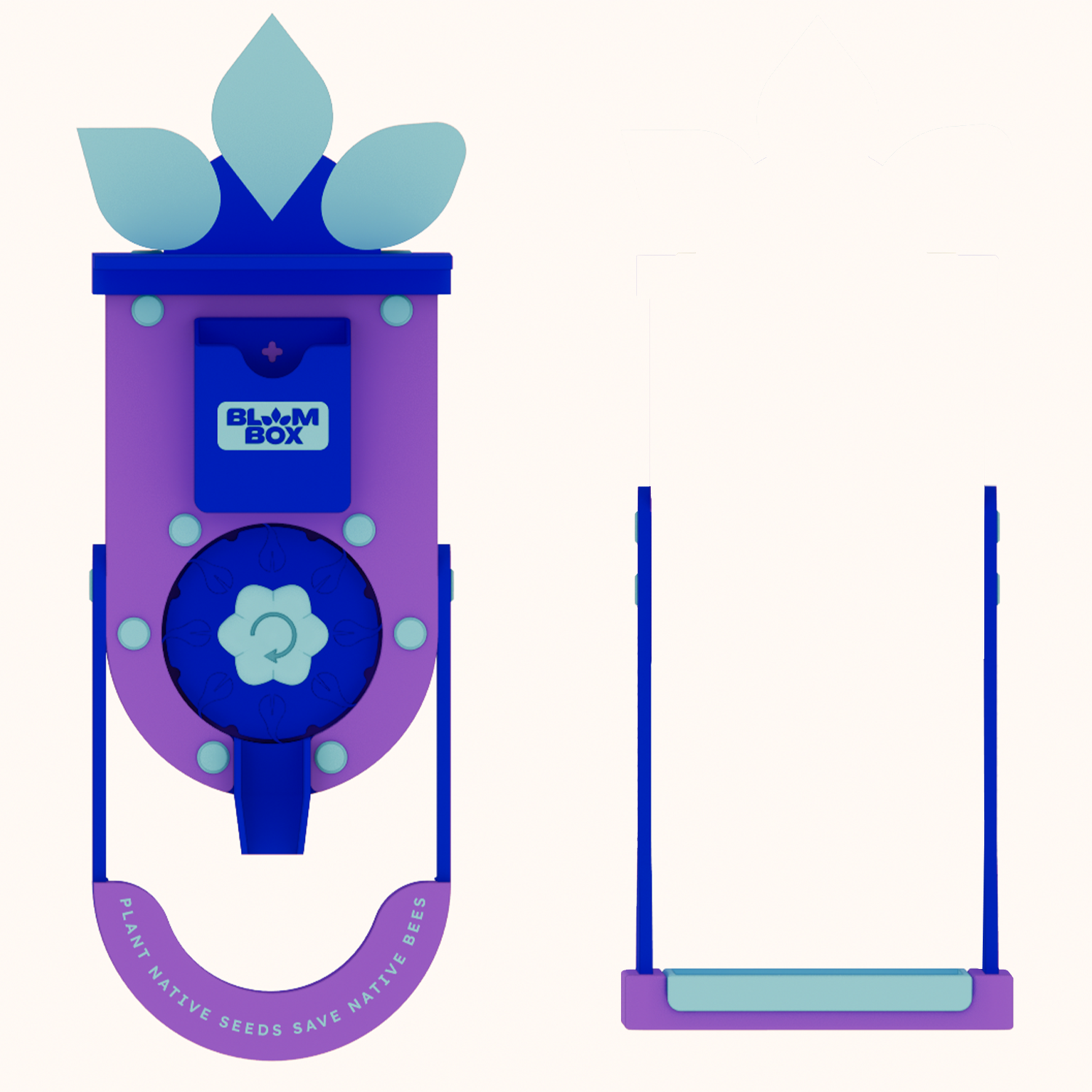

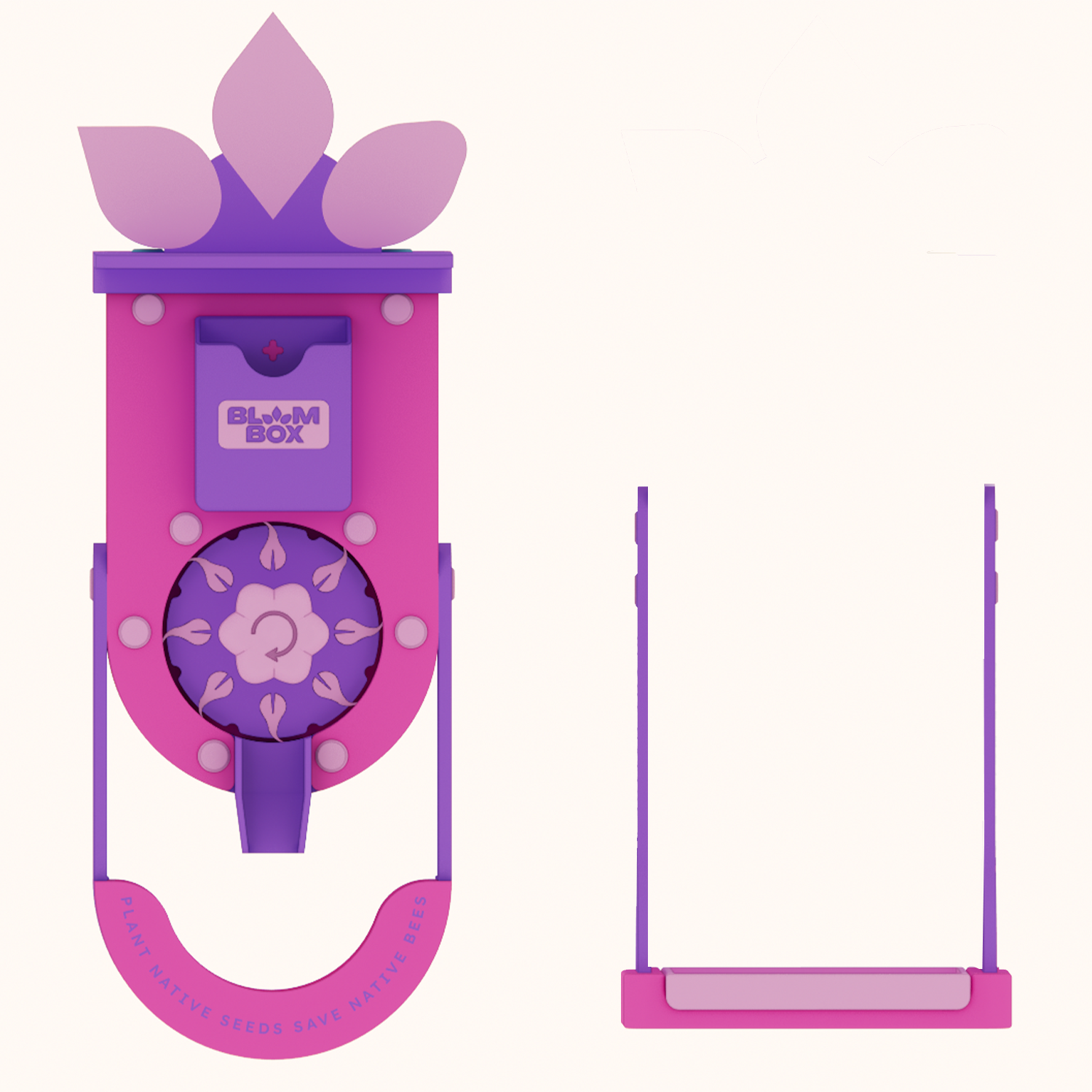

The main components of each BloomBox is 3D printed using polylactic acid (PLA).

Why 3D Printing?

3D printing is an additive technique that essentially generates little to no waste or post processing, while being flexible in customization and color options.

We decided to adopt 3D printing based on the fact that the first BloomBox was initially made from wood. While wood is a regenerative material, it produces more waste through off-cuts from larger wood panels. Additionally, wood would need to be sealed for weatherproofing and paint, which often uses toxic chemicals that are harmful to the environment and health, contradicting one of the key points of this project.

Cost also played a factor into this decision. Most of the plywood in the United States is shipped internationally from the Baltic regions. With political and economic tensions that affect the supply chain, we want to ensure these products are as affordable as possible.

Wait, isn’t plastic bad for the planet???

You are right and totally valid to have reservations!

While PLA itself is considered a plastic, it is derived from renewable sources such as sugar cane, corn starch, and other biomass which is biodegradable via industrial composters.

3D printing technology has come a long way and there are more innovative materials to choose from. We will keep exploring sustainable alternatives that maintain consistent quality.